The Great Influence of 华体会体育·(中国)股份有限公司官网 Assembly Mechanism

The accuracy of reducing the influence of moisture on any type of printed circuit board From data fusion, 华体会体育·(中国)股份有限公司官网 layout, prototype design, 华体会体育·(中国)股份有限公司官网 engineering, assembly to packaging and order delivery, attention should be paid to the influence of moisture on 华体会体育·(中国)股份有限公司官网 manufacturing to avoid 华体会体育·(中国)股份有限公司官网 function damage and other problems In addition, let's have a deep understanding of the important measures to control the humidity level during the laminating process, the control of 华体会体育·(中国)股份有限公司官网 components and the control of storage, packaging and transportation

What factors affect 华体会体育·(中国)股份有限公司官网 assembly mechanism

Rigid/flexible printed circuit board assemblies, cable bundles, boxed assemblies or harness 华体会体育·(中国)股份有限公司官网 assemblies are made of various types of materials, whICh fully meet the requirements of the powerful mechanical and electrical efficiency of electronic products used in all major industries in the world. It requires high frequency, low impedance, compactness, durability, high tensile strength, low weight, multi-function, temperature control or moisture resistance. 华体会体育·(中国)股份有限公司官网 can be divided into single layer, double layer or multi-layer according to the complexity of the circuit. Among all the serious problems that should be noticed at the beginning of 华体会体育·(中国)股份有限公司官网 manufacturing, humidity or humidity is the main factor causing electronic and mechanical failures in 华体会体育·(中国)股份有限公司官网 operation.

How does damp bring great trouble to 华体会体育·(中国)股份有限公司官网?

Because it exists in epoxy glass prepreg, it diffuses in 华体会体育·(中国)股份有限公司官网 during storage, and when absorbed, moisture can form various defects in 华体会体育·(中国)股份有限公司官网 components. The wet processing time in the 华体会体育·(中国)股份有限公司官网 manufacturing process exists in microcracks, or can form a home in the resin interface. Since the high temperature and vapor pressure are parallel to the lead-free mechanism in the 华体会体育·(中国)股份有限公司官网 assembly, this may cause moisture absorption.

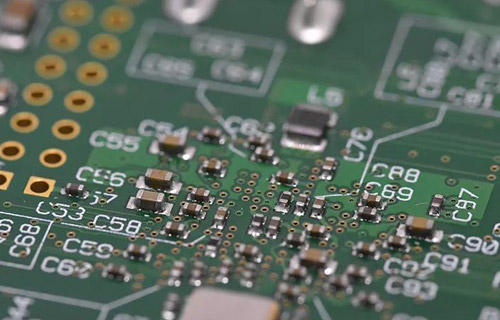

Circuit board

Due to the failure of adhesives and stickiness in printed circuit boards, delamination or cracking will occur, and moisture will make it possible for metals to migrate, resulting in a low impedance path of dimensional stability changes. With the decrease of glass transition temperature, the increase of dielectric constant and other technological damage, the switching speed of the circuit will be reduced and the propagation delay will be increased.

The main effect of moisture in 华体会体育·(中国)股份有限公司官网 is to reduce the quality of metallization, lamination, solder resistance and 华体会体育·(中国)股份有限公司官网 manufacturing process. Due to the influence of moisture, the limit of thermal stress becomes too high with the decrease of glass transition temperature. Sometimes it will lead to serious short circuit, which will lead to moisture entering and lead to ionic corrosion. Other common characteristics of moisture absorption in printed circuit board assemblies include flame retardancy or delamination, new (DF) dissipation factor and (DK) dielectric constant, thermal stress on plated through-hole, and copper oxidation.

Method of reducing moisture in air 华体会体育·(中国)股份有限公司官网 manufacturing:

Whether SIMple or complex technologies are used in 华体会体育·(中国)股份有限公司官网 manufacturing, many operations in 华体会体育·(中国)股份有限公司官网 engineering require wet treatment and removal of residual moisture. Raw materials used in 华体会体育·(中国)股份有限公司官网 manufacturing need to be protected during storage, handling and 华体会体育·(中国)股份有限公司官网 assembly. The following is a short guide to implementing control at each stage of 华体会体育·(中国)股份有限公司官网 operation:

1. Lamination

Lamination is a dehydration step in 华体会体育·(中国)股份有限公司官网 manufacturing because the core and prepreg are stacked together to bond the layers into the laminate. The main control factors in the laminating process are temperature, time used and heating rate. Sometimes, when the dryness is low, measures will be taken to reduce the vacuum to reduce the possibility of attracting internal voids to absorb water. In this way, gloves can be used to control the moisture level when handling prepreg. This reduces cross contamination. The non corrosive humidity instruction card shall be flexible to consider the humidity level when required. Laminates should have a short cleaning cycle and be stored effectively in a controlLED environment, which helps prevent water pockets from forming in the laminate.

2. Post lamination process and 华体会体育·(中国)股份有限公司官网 assembly

After drilling holes in 华体会体育·(中国)股份有限公司官网 manufacturing, photographic imaging and etching operations, the moisture absorption rate captured in the wet process is higher. Screen printing curing and solder mask baking are the processing steps to eliminate moisture. This is more effective in reducing moisture absorption levels by minimizing the holding time interval between steps and even being keen on managing storage conditions. By ensuring that the 华体会体育·(中国)股份有限公司官网 is sufficiently dry in the early stages of 华体会体育·(中国)股份有限公司官网 lamination, it helps to reduce baking operations after lamination. In addition, high-quality surface treatment is used to prevent cracks during drilling, and the moisture of residues is removed by baking before the hot air solder leveling process. Baking time shall consider the determination level of water content, complexity of 华体会体育·(中国)股份有限公司官网 manufacturing, 华体会体育·(中国)股份有限公司官网 surface treatment and sufficient thickness required for the circuit board.

Therefore, it is important to know the latest situation of the impact of soil moisture on 华体会体育·(中国)股份有限公司官网 manufacturing to avoid failures, damage and short circuits on 华体会体育·(中国)股份有限公司官网, and increase rework costs Now, researchers are about to launch more advanced solutions, using environment-friendly 华体会体育·(中国)股份有限公司官网 technology to control the moisture element in the following steps: 华体会体育·(中国)股份有限公司官网 manufacturing, thus saving time, energy and cost

然后

联系

电话热线

13410863085Q Q

微信

- 邮箱